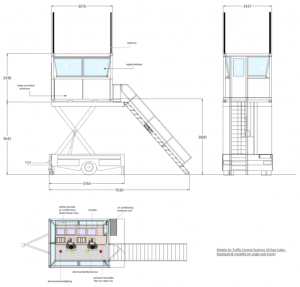

Compact Trailer Mounted VCR

The Compact Trailer Mounted Elevating VCR provides operational space for up to 2 ATC Controllers (ATCOs). It is a self-contained, air transportable solution with sufficient storage for all the external ATC systems, deployment tools and equipment. A small team of 2-3 personnel can deploy and be operational within 2 hours of arrival. The internal ATC Equipment fit is designed with the customer to suit their specific needs and aircraft movement levels.

The 5 Bay operator’s console is designed to house a wide range of communications equipment including Radios, Voice Communications Switch, Voice Recorders, crash telephone, Meteorology equipment, and a UPS to provide hold up power for critical systems.

Sitting on a single axle active air suspension the trailer can be raised to a higher ride height for improved rough terrain performance. Hydraulic drop legs provide stability when deployed. Side belly lockers allow all deployment equipment to be packed on the trailer. The VCR Cabin can be dismounted for air transport.

The personal safety of technical and operational personnel is considered in all aspects of the MATC design with safety systems built into the mechanical, hydraulic, and electrical elements of the system. Operational safety is provided by resilient and redundant solutions in accordance with customer requirements.

ATC Systems Overview

Taken during installation of a larger cabin this image indicates the amount of equipment that can be installed into a 5-bay console. Equipment shown is customer specified and MATC is happy to work with all major suppliers. A hinged, LED under-lit counter-top allows engineering access when complete.

Easy to install roof mounts allow antennas, obstruction lights, meteorology sensors, ident beacons, and any other equipment to be mounted on the roof prior to elevation. A Connection panel on the balcony provides the interface to the various systems.

The MATC Compact Elevating Trailer provides a fully equipped, transportable, environmentally controlled, and insulated workspace that is designed to be like a static ATC Tower. It provides the same facilities as might be expected from any VCR but is transportable to where it is needed.

The Compact Tow Bar Trailer is a self-contained, air transportable VCR that can be deployed in under 2 hours. Stairs, railings, antennas, and all ATC equipment are stored onboard the trailer. A small trailer mounted generator is available if required.

For air-transport the VCR cabin is removed from the trailer by disconnecting and stowing the umbilical cables, unlocking the corner ISO-Locks and simply winching onto the aircraft ramp.

Just like the larger MATC systems seen here the VCR cabin is designed to be airlifted and strops can be attached to the ISO-frame corners to under sling from the aircraft. The trailer can also be specified to have lifting eyes if required.

All hydraulics are equipped with check valves to prevent failure and the main lifting Ram is positive drive up and down. Safety Locks are also raised in the intermediate and fully raised position to prevent any possibility of accidental lowering.

Electrical Systems are installed to IEE 18th Edition Regulations. Residual Current safety devices are installed on the mains distribution circuits and the UPS distribution circuits, and an independent 3 rd party test is carried out on every installation. Earth Plates and Earth Rods are provided to ensure good earth connections can be achieved during deployment.

Personal safety features include LED lighting on all steps, safety rails on stairs and balcony access, and karabiner safety rails recessed into the roof to assure safe working at height when deploying antennas and obstruction lights.

MATC NEWS

Find out why our customers love our products, and how they help them achieve success.

Testimonials

MATC are a responsive, flexible contractor. They enabled us to support the demands of our end user customer through program reviews, training, and product acceptance events. At all stages we were kept informed on progress with regular project updates provided for the duration of the contract. MATC displayed excellent programme and risk management procedures throughout which kept this complex project on track.

The motive for purchasing the Mobile Air Traffic Control Tower was to provide all airports in Lithuania with a quick deployment back up ATC capability within SWIM enabled features by using common fibre links that have been installed at all Lithuanian international airports. Mobile ATC Systems were flexible so we (Oro Navigacija) were able to use in house facilities to integrate the MATC Cabin to meet our needs; this has worked very well for us.

Mobile ATC Systems Ltd helped us to carry out a complex shipment requirement from the manufacturer with a professional approach and good communications. Everything was done in a timely manner and there were no issues with the services we received. We would be happy to engage with Mobile ATC for future service needs.

MATC delivered three ORCs to UNICEF for outreach primary healthcare in Eritrea. Colin Chapman delivered end user training in Asmara to the Health Ministry and UNICEF personnel. Geoffrey Acaye, Chief of Child Survival and Development said “Thank you too for being so supportive in this phase of the project. We will certainly reach out to you for any further support whenever required. I am confident that this initial phase will stimulate the interest of the Government and donors to expand further”.

Accreditation

Airport Suppliers

ISO 9001:2015 Certified

East Midlands Chamber of commerce

FAQ's

The Compact Tow Bar trailer is more compact and lighter than the other trailers and whilst it needs to be towed by an HGV vehicle equipped with a tow took it is cheaper, easier to store and more suitable for disaster relief operations, events or small airports requiring a temporary solution.

There are a number of belly lockers on the trailer for storing antennas, stair rails, tool kits and antenna mounts. The main stairs are stored in a roller equipped locker close to where the fold down access stairs are which enables easy installation. Additional lashing points in the VCR can be provided to allow storage of transit cases in the Ops area.

The small trailer is designed to be operated at 2 heights, fully elevated and lowered. At the maximum height, the maximum wind speed calculations show wind speeds up to 55 mph can be sustained. However, lashing restraints are provided and can increase the operational wind speed significantly. MATC advises each customer to do their own risk assessment based on local regulations for the risk of injury when entering and leaving the VCR during high wind speeds as this is a greater risk to operators than overturning.